for Foundry

| SIZE mm | INCH | Speed [m/s] | Max. Speed[RPM] | Type | Box | M. box |

|---|---|---|---|---|---|---|

| 115x7x22 | 4-1/2 |

80m/s |

13,300 | 25 | 200 | |

| 125x7x22 | 5 | 12,200 | 25 | 100 | ||

| 150x7x22 | 6 | 10,200 | 25 | 100 | ||

| 180x7x22 | 7 | 8,600 | 25 | 100 | ||

| 230x7x22 | 9 | 6,600 | 10 | 40 |

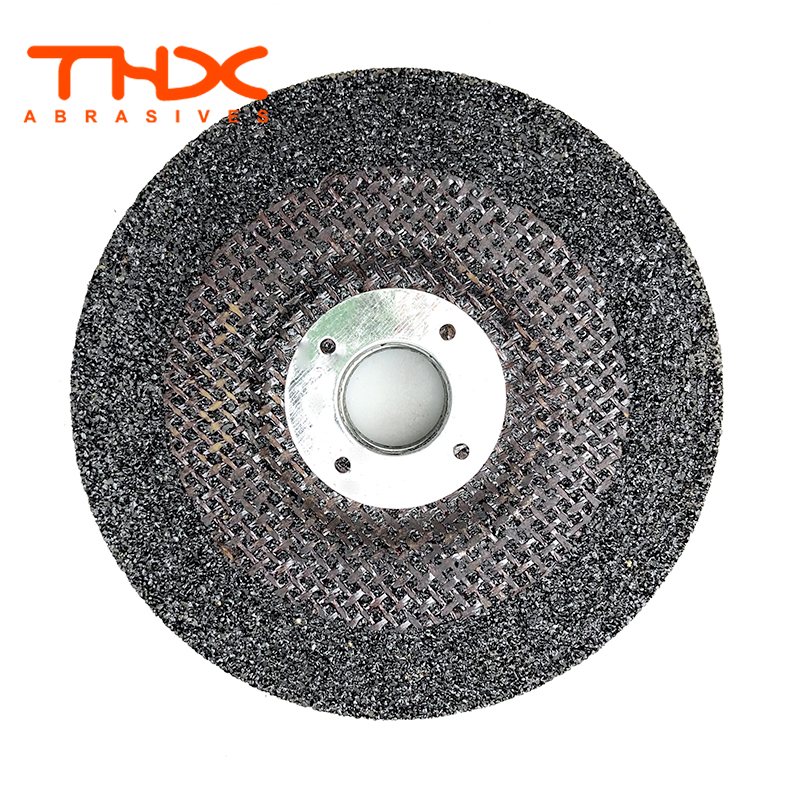

THXabrasives Strong grinding wheel for casting. Used in high power angle grinder.

In order to meet the difficult operating environment of foundries using pneumatic turbine grinders and high power high frequency or electric Angle grinders, we have developed high power grinding wheels that meet high quality and safety standards.

High results can be achieved in grinding materials such as steel, flake graphite cast iron, sand impregnated cast iron, cast iron, ductile iron and so on.

The most common applications in the foundry are general sand removal, surface grinding, chamfering and deburring.

|

|

| Grinding wheel

2.5 pieces of glass fiber reinforced mesh.

Higher strength than 3 pieces.

|

Grinding wheel

European and American forms,

3 pieces of glass fiber reinforced mesh.

|

● Applicable Tools: Angle grinder.

Workpiece material:

Grinding metal,steel,Aluminum alloy, casting .

Applications:

1.Surface grinding 2. Grinding weld 3. Chamfering 4. Deburring 5.Oxide skin grinding