For Stone

| SIZE mm | INCH | Peripheral Speed [m/s] | Max. Speed[RPM] | Type | Box | M. box |

|---|---|---|---|---|---|---|

| 100x7x16 | 4 | 80m/s | 15,300 | 25 | 200 | |

| 100x7x15 | 4 | 15,300 | 25 | 200 | ||

| 115x7x22 | 4-1/2 |

80m/s |

13,300 | 25 | 200 | |

| 125x7x22 | 5 | 12,200 | 25 | 100 | ||

| 150x7x22 | 6 | 10,200 | 25 | 100 | ||

| 180x7x22 | 7 | 8,600 | 25 | 50 | ||

| 230x7x22 | 9 | 6,600 | 10 | 40 |

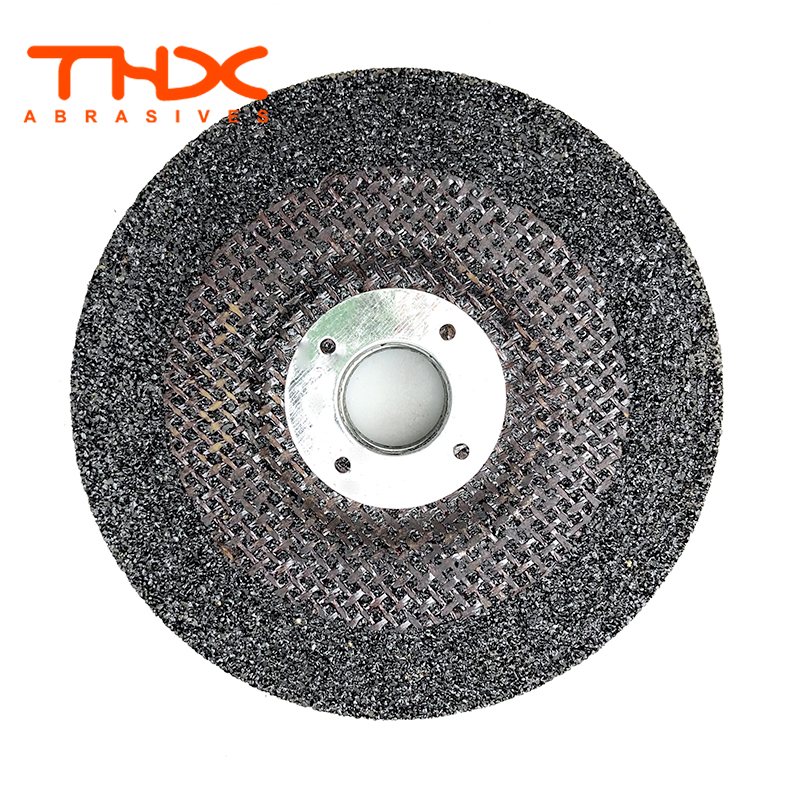

THXabrasives grinding wheels for Stone are manufactured with a particularly high proportion of C.

Resin grinding discs are suitable for rough grinding of metallic and non-metallic materials. It has high machining accuracy when working on fillet welds. After grinding, the workpiece can be directly galvanized or painted. For different materials, grinding discs with different grit can be selected.

|

|

| Grinding wheel

2.5 pieces of glass fiber reinforced mesh.

Higher strength than 3 pieces.

|

Grinding wheel

European and American forms,

3 pieces of glass fiber reinforced mesh.

|

● Type: T27

● Applicable Tools: Angle grinder.

● Support: OEM, ODM, Small batch customization, Free Design.

● One-stop purchase of cutting discs, grinding discs, flap discs, stripping discs, industry bristle discs.

Workpiece material:

- Grinding of gray sand brick

- Grinding of artificial stone

- Grinding of marble

- Grinding of natural stone

- Grinding of Concrete products.

Applications:

1.Surface grinding 2. Chamfering 3.Oxide skin grinding

Attention:When grinding stone with grinding disc, it usually produces large dust. Therefore, it is recommended to wear appropriate respiratory protective tools during work.